| SPECIFICATION | MODLE | SM-6S/900M | SM-6S/900V | SM-6S/900P | |

| Gear Transmission | Inverter | PLC Touch Screen | |||

| Working Ability | Shuttle Speed | RPM | 120 -150 | ||

| Nos. Of Shuttle | Set | 6 | |||

| Weft Inserting Speed | RPM | 720 - 900 | |||

| Weft Density | P / Inch | 8 - 16 | |||

| Lay Flat Width | MM | 400 - 900 | |||

| Yarn Package Size | Weft Tube | MM | I.D. (23 - 28) ψ | ||

| Maximum Weft Package | MM | 105 ψ | |||

| Warp Tube | MM | I.D. (23 - 28) ψ | |||

| Warp Creel Bobbin | PCS | 800 | |||

| Cloth Winder | Roller Width | MM | 1000 | ||

| Torque Motor | KG | 10 KG-CM | |||

| Power | Main Motor 3P | KW | 5 HP AC Motor | 5 HP AC + Inverter | 5 HP AC + Inverter |

| Take-Up Speed Construction | KW |

Gear Box Transmission |

Gear Box Transmission |

PLC & Touch Sreen | |

| Weaving Density Construction | KW | Gear Box | Gear Box | 1/2 HP AC Motor | |

| Fan Motor 3P | KW | 1/2 HP | |||

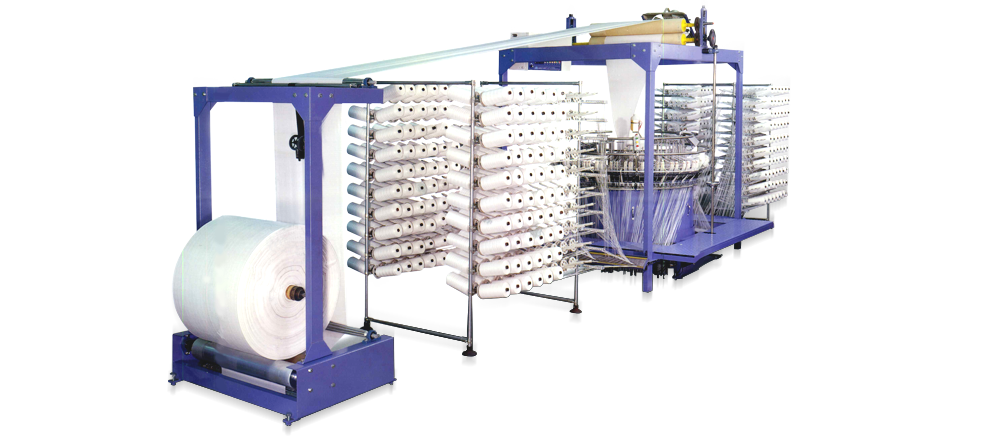

| Layout & Packing | Dimension L × W × H | M | 10.1 × 2.54 × 2.9 | ||

| Packing G.W. | MT | 2.9 | |||

Optional device available upon request:

1. Extra cloth winder for 1800 mm width, Thermo slitting device.

2. Gusseting device.

WEFT FEED WITH EQUAL TENSION LARGE WEFT PACKAGE 100MM ψ

A coppwe brake of weft tension control ensure the equal tension, independent of whether the weft package is full or nearly empty.

Accurate weft break sensor provided by magnetic sensor detecting of its weft tape finished or broken, even very poor working environment such as poor lighten, dirty dust or stains wont affect the performance.

The shuttle accepts large yarn packages up to 100 mm ψ makes high productivity.

FRICTION TYPE CLOTH WINDER WITH TORQUE MOTOR DRIVEN

Two friction roller driven by a torque motor and adjustable cloth tension provides Very tightly winding up cloth roll. A very big winding size up to 100 cm us acceptable.

Exchangeable switch equipped for facilitating loading and unloading clot roll.

Standard width is 1000 mm and an exta width up to 1800 nn with open device is acceptable as an optional device.

UNIFORM TENSION WAPP - FEED SYSTEM ENSURE WEAVING VERY LOW DENIER & RECYCLED FLAT YARN

Our circular loom can weaving very low denietape due to very low friction between warp tapes from sool creel to warp tension balancer. All warp pass smoothly with individual tension compensator, which easy for operation and a minimum loss of tape during the weaving process.

A coppwe brake of weft tension control ensure the equal tension, independent of whether the weft package is full or nearly empty.

Accurate weft break sensor provided by magnetic sensor detecting of its weft tape finished or broken, even very poor working environment such as poor lighten, dirty dust or stains wont affect the performance.

The shuttle accepts large yarn packages up to 100 mm ψ makes high productivity.

FRICTION TYPE CLOTH WINDER WITH TORQUE MOTOR DRIVEN

Two friction roller driven by a torque motor and adjustable cloth tension provides Very tightly winding up cloth roll. A very big winding size up to 100 cm us acceptable.

Exchangeable switch equipped for facilitating loading and unloading clot roll.

Standard width is 1000 mm and an exta width up to 1800 nn with open device is acceptable as an optional device.

UNIFORM TENSION WAPP - FEED SYSTEM ENSURE WEAVING VERY LOW DENIER & RECYCLED FLAT YARN

Our circular loom can weaving very low denietape due to very low friction between warp tapes from sool creel to warp tension balancer. All warp pass smoothly with individual tension compensator, which easy for operation and a minimum loss of tape during the weaving process.